How To Program Cnc Wood Router

Videos you watch may be added to the TVs watch history and.

How to program cnc wood router. Use some CADCAM software to complete CNC programming. Up until the past 20 years or so CAD design had been limited to those who could afford expensive software programs. Other CNC routers may have other types of buttons to signal this command.

Write G code directly for programming 2. Become a better woodworker by viewing these how-to woodworking videos. The computer programming and design that is needed to create the files that are sent to the CNC machine is often referred to as CAD software.

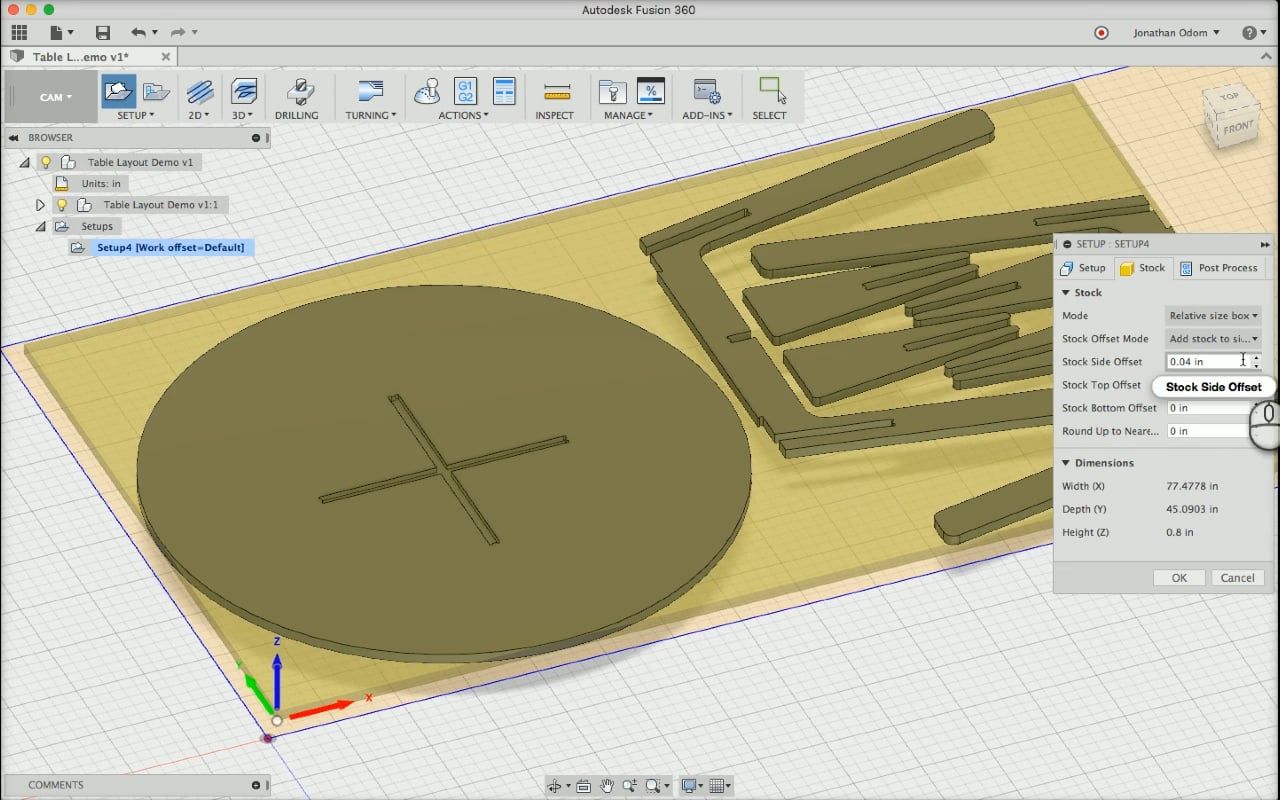

There are other extensions that will work but these two are the most common. Fusion 360 is the software of choice for thousands of CNC router owners With Fusion you can design any part imaginable and output the model to G-Code that can be read by your CNC router CADCAM is a huge subject where knowledge of mechanical engineering is essential to. Allow the router to engrave the substrate.

The CNC system allows a woodworker to program in the specific cuts he or she wants made then let the machine execute the program. From design to manufacturing stage a wood CNC router uses three different kinds of software namely CAD CAM and CNC control software. But these two methods have certain shortcomings.

The process of designing a part for your CNC router begins with a CAD program. Whether its a few wooden gears needed to build a mechanical wall clock robot or an anemometer a CAD program can help you create just about any size gear pattern. Common Sense About How to Program A Woodturning Project for CNC Wood Lathe.

So most people now Both use CADCAM software to create the initial CNC program and then use G-code programming to edit the g-code from the CADCAM software. So our design should be created in the space between the left boundary and the central line. CAD is an acronym for Computer Aided Drawings.