How To Grind A Lathe Parting Tool

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup.

How to grind a lathe parting tool. If you break off the end you just grind a. Then I used the disk sander to round off the corners and the wood end of the parting tool. Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting.

For our second project we were given two new 38 lathe bits and had to learn to grind a turning tool parting tool facing tool and a threading tool for 34-10 ANS threads. This flattens and dulls the cutting edges but you can use these flat edges as a guide to maintain the desired profile. Put the tool on center if you put the tip below center you run the real risk of having the part roll over the bit this breaks things.

Do not grind on the top or sides just the front-end. I intend mostly to use them for roughing and for preliminary grinding of reliefs on drills. Inspect the parting tool closely before using.

Took it over to the 1 belt sander cleaned up the blade a little more and fine tuned the wood edges. Instead grind the profile first by feeding the nose of the tool into a sharpening machine. Grinding down too far will have the effect of reducing the blade width and so limits the depth the tool can be plunged.

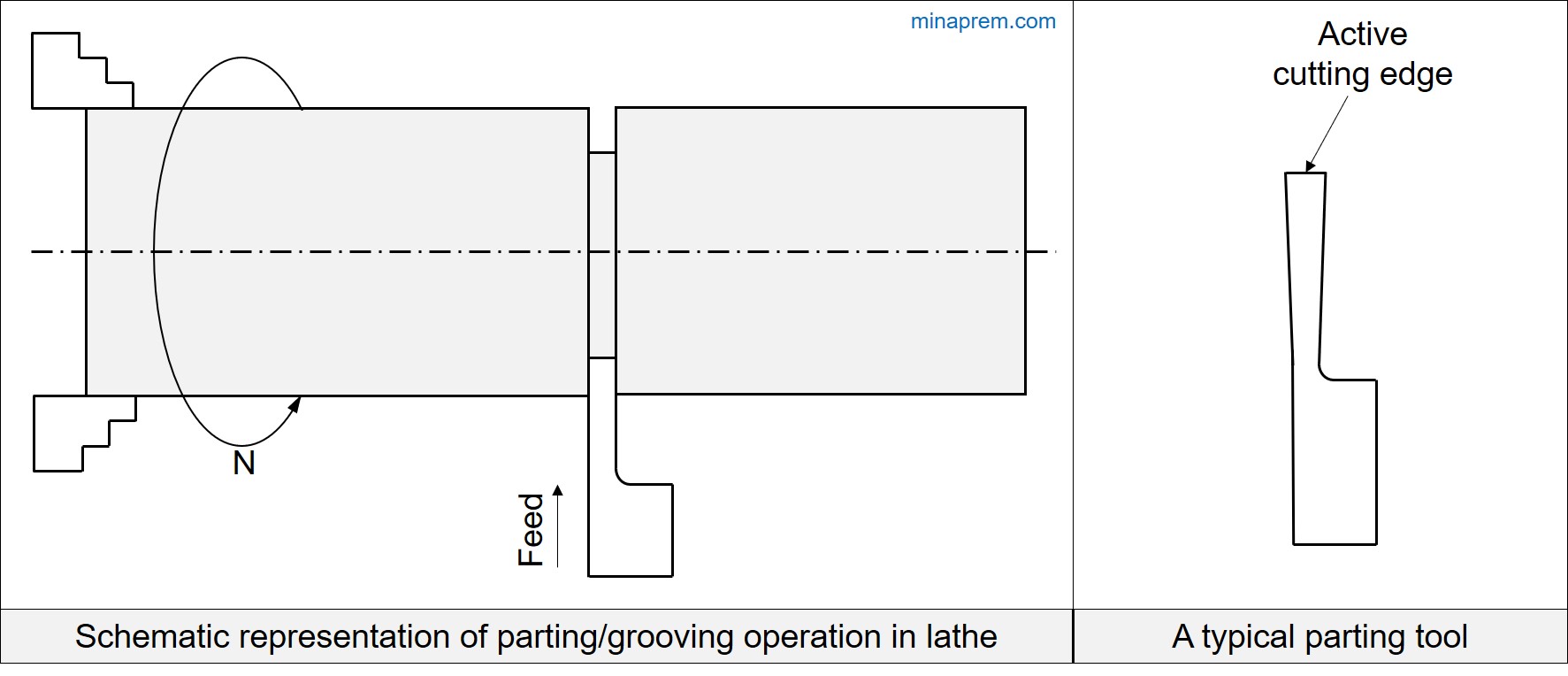

This video covers how to properly grind the tool how to set the tool so it is ri. Grinding the side face of the tool. Edges faceedge need to be 90 so must be held square to wheel.

I was working on a handle for a gouge blade. If using HSS parting blades grind andor hone the cutting edge to ensure its sharp. Maximize Cutting Tool Stiffness.