How To Build Your Own Cnc Wood Router

He also made a few sweet upgrades.

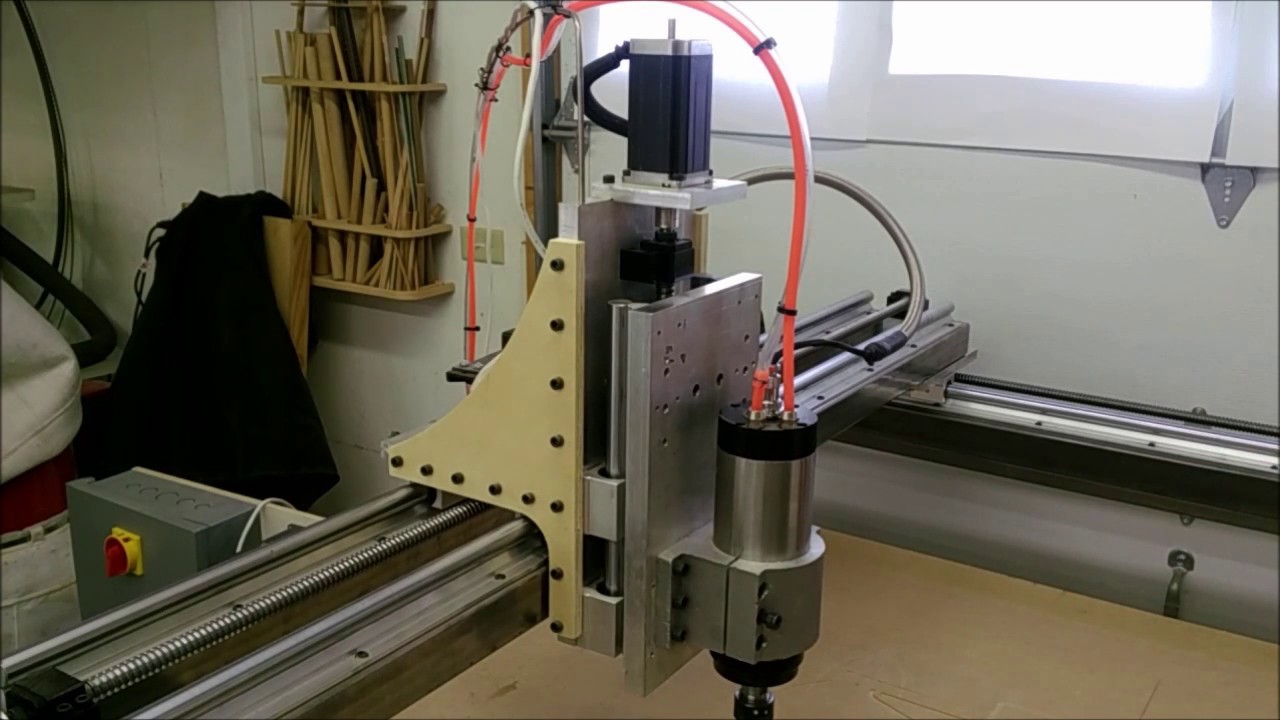

How to build your own cnc wood router. He added an emergency stop button which any experienced CNC operator can tell you will come in handy sooner or later. This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it. With a working area of 24x48 you can build this for a lot less than the cost of a similar commercial CNC router.

It would be just like a professional is next to you guiding you every step of the way. The mechanical parts he had to. You might also need to invest in specialized tools such as drive positioning screws linear slides stepper motors and a.

A CNC machine is probably the most useful tool a hobbyist can own but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend. This is a very good router that can be built at a reasonable price using readily available materials. A chop saw wood lathe drill and a drill press and finally a table saw nothing fancy but now with the CNC router he has a world of possibilities for projects.

A compact router baltic birch plywood some basic hardware and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. This is the second DIY CNC Router I made after learning a lot from building the first version. This is my favorite step as it uses the fewest and most basic fabricated components is simple to complete and gives you a sense of achievement without doing a whole lot.

To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft. All you need to do is assembl the machine or find someone in your area that can assemble the machine We are building a list of individuals to help assemble in your area. CNC wood router can make many instruments like piano guitar violin and others.

Building your own 3-Axis CNC router is both fun and educational. To provide additional support for the X-axis he set two pieces of tube steel into notches in the front and back of the machine. Making musical instruments is also a good way to run your CNC machining business.