What Are The Five Safety Precautions Use In Machine Workshop

Health and Safety Executive Working safely with metalworking fluids A guide for employees 1 of 5 pages Introduction This leaflet aims to help employees who work with metalworking fluids understand the main risks to their health.

What are the five safety precautions use in machine workshop. Never use hands to remove chips and curls. Safety Precautions Always Wear Approved Safety Glasses Rollup Sleeves Remove Tie And Tuck In Looseclothing Never O Lathe Machine How To Remove Lathe. Always stop the machine for making measurements and adjustments.

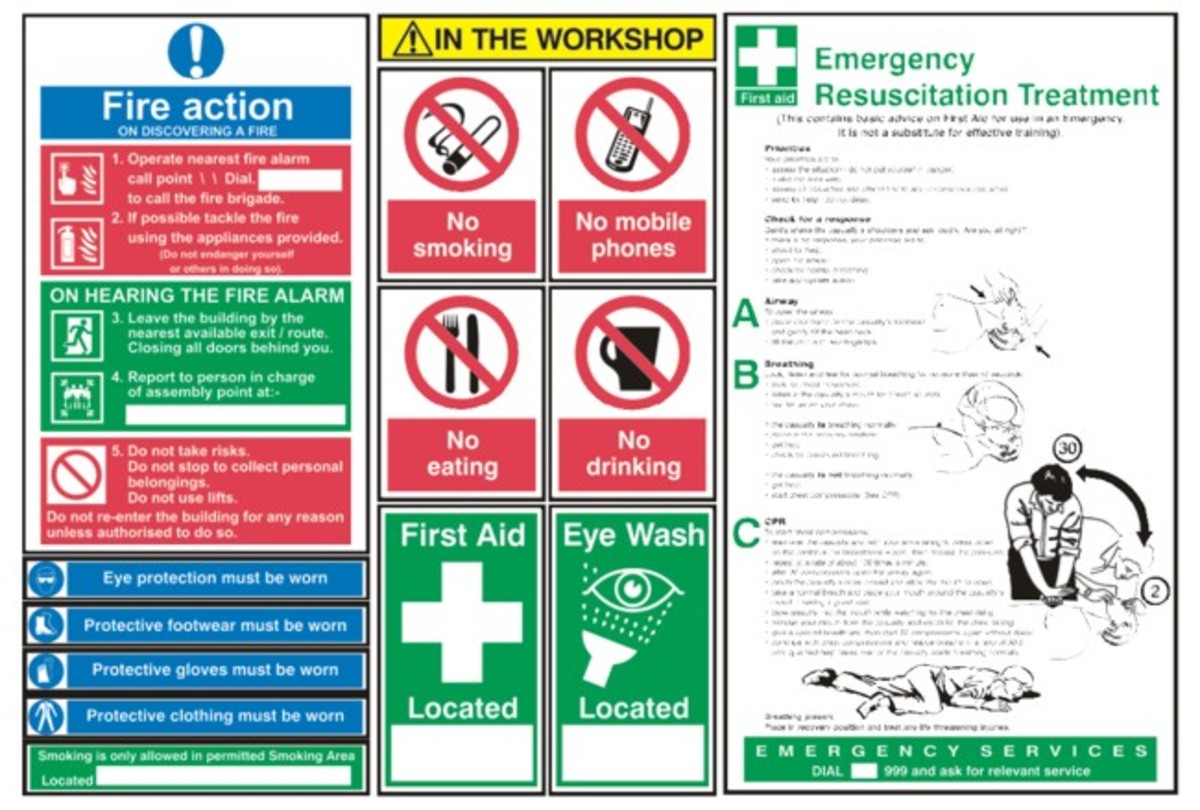

Safety precautions for Milling Machines. Untidiness Overcrowded passageways objects on the floor grease or oil on the floor. This guide is an introduction to managing the risks associated with use.

Always clamp the work and tool properly with correct size of work and tool holding device. One should always be sure that all guards are in place before running the machine. Safety Precautions while Working on Lathe Machine.

Specific safety guidelines for some of the machine process like lathe drilling shaping planning slotting grinding milling and finishing operations are also described in the following. Dont wear neck ties or loose turn clothing of any kind. Many are blaming themselves today because of the problems they had due to their carelessness in workshops.

Adjust the upper guard assembly to within ¼ inch of the stock prior to starting the machine. A guide to machinery and equipment safety is provided to assist persons conducting a business or undertaking PCBU and workers to comply with their duties under the Work Health and Safety Act 2011 the Act and the Work Health and Safety Regulation 2011 the Regulation. Not paying attention to safety rules.

Shop Safety Checklist Safety Checklist Checklist Safety. Machine Safety at Carleton. Paying no regard for others working near you.