Types Of Measuring Tools In Workshop

The markings will never fade ensuring youll be able to mark out correct.

Types of measuring tools in workshop. Therefore for removing those errors from a workpiece some measurement tools are devised by engineers such as surface texture measurement device tolerance measurement device screws threads measurement device and so on. Bevel Protractor is an angular measuring instrument capable of measuring angles with a least count of 5. Calipers are classified into two types.

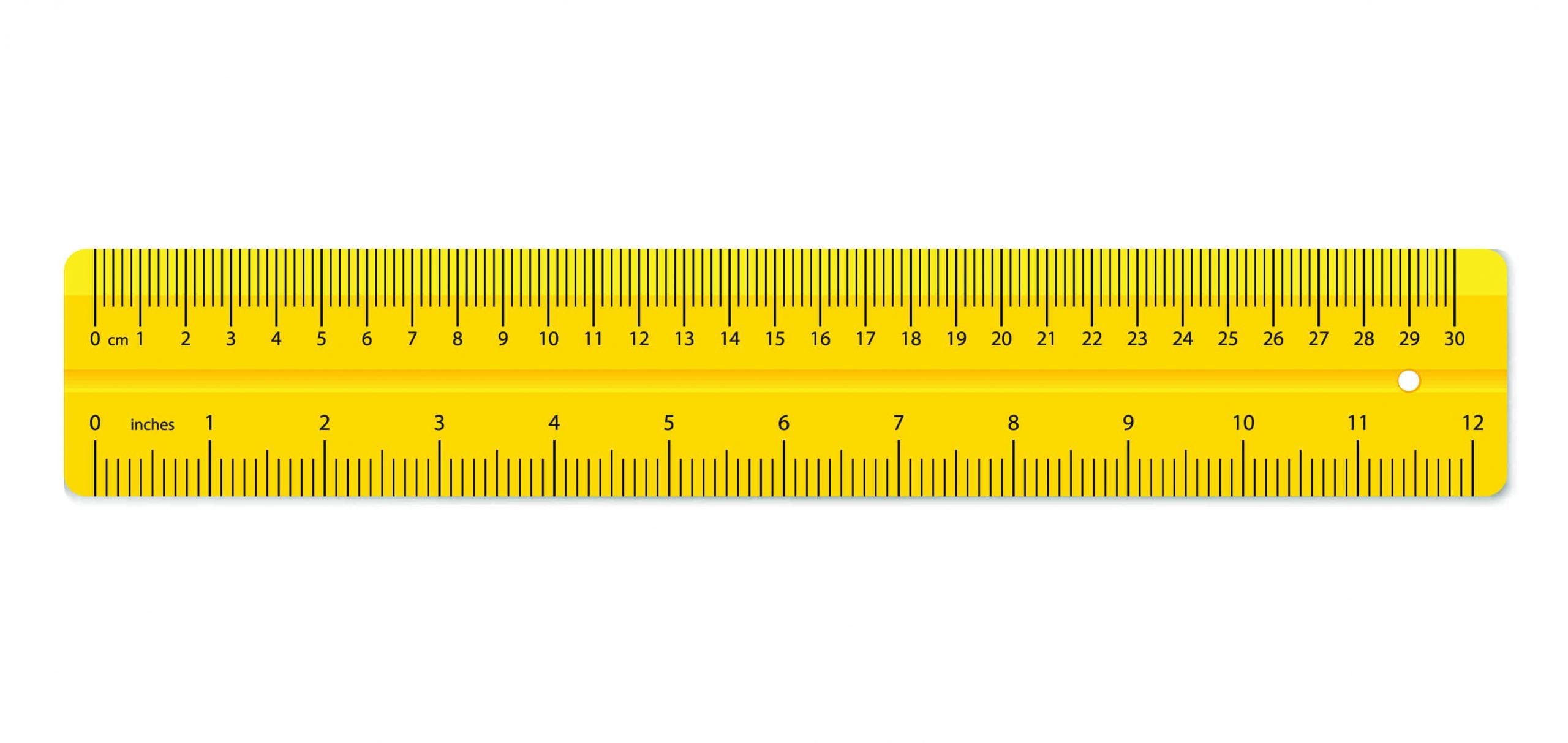

Gauge is the tool used by engineers to. Turn the ruler to the corresponding scale factor. For instance if the plans read ¼ inch equals one foot you will use the ¼ inch scale on the ruler.

Climate and environment tools. Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting Workshop. An experienced worker can achieve -005mm in the measurement.

The detailed explanation of 10 Measuring Tools was HERE. Measuring Tools are used to measure any component wrt. Each set consists of a tapper tap intermediate tap and plug or bottoming tap.

At a minimum it serves as five tools in one including. Marking tools in workshop are Surface GaugeSurface PlateMarking TableScriberPrick PunchCenter PunchDividerTrammelBevel Square. Some of the Measuring Tools used in Fitting Workshop are as follows.

Hand tools can accomplish a large portion of carpentry work given enough knowledge proficiency and time but power tools are a step-up in every aspect. Workshop Measuring Tools A private collection of drawing instruments slide rules and mechanical calculators as well as a few microscopes and miscellaneous items. A simple protractor is a basic device used for measuring angles with the least count of 1 or ½.