How To Sharpen A Metal Lathe Parting Tool

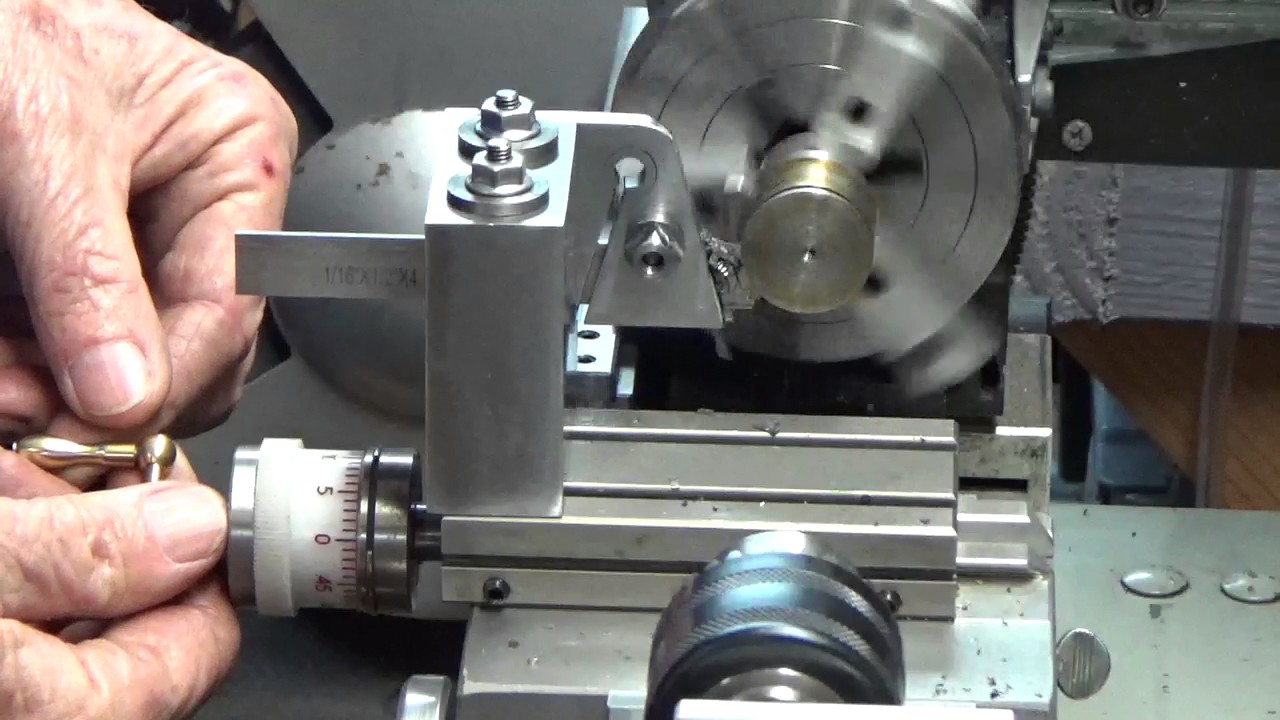

Shown below is what Ive put together to achieve the level of accuracy desired.

How to sharpen a metal lathe parting tool. Maximize Cutting Tool Stiffness. This guide will give you the basic steps and equipment needed to keep your lathe tools in top shape. If you sharpen these using a V-pocket be careful the tip of the tool is above the centerline of the wheel.

Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds. Next look up the typical angles for the workpiece material and then follow the steps in Figure A2. Inspect the parting tool closely before using.

In this example we are making a normal right handed tool for the lathe. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. In general the method is to use either a grinder or belt sander and then finish with a hone.

Begin by dressing the grinding wheel. Generally ground to 45 but 35 may work better on softer woods. In particular the angles must be precise for best cutting action.

The end result should be the point of the parting tool be ground to a sharp squared of point. Trusted China Suppliers Verified by SGS. The work was fed across the edge of the grinding wheel with a light inward pressure to make the cut.

As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner. Next time I will decrease the feed rate. In general the method is to use either a grinder or belt sander and then finish with a hone.