How To Setup A Parting Tool On A Lathe

Feed by hand and slowly at first--you will develop a feel for feed rate 4.

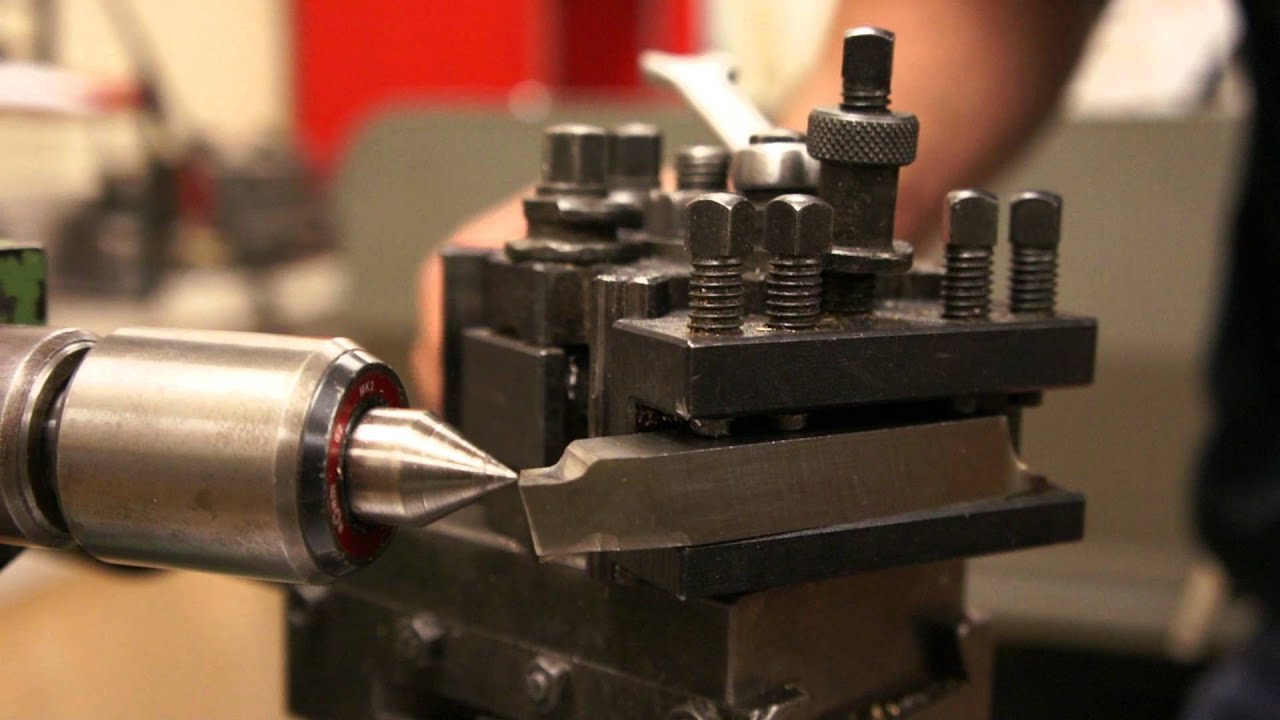

How to setup a parting tool on a lathe. Keep advancing the tool until you get a steady chip curling off the workpiece and then try to maintain this cutting speed. When ground flat on the platform not vertical it will. Be sure your parting tool is on center I like to use a 6 scale and trap it between the work and parting tool---when it is straight up--you are good to go.

Be sure tool is sharp 3. We recommend to use a sub-spindle if available. I shaped the end of the blade like the Sorby Parting Tool double angle look.

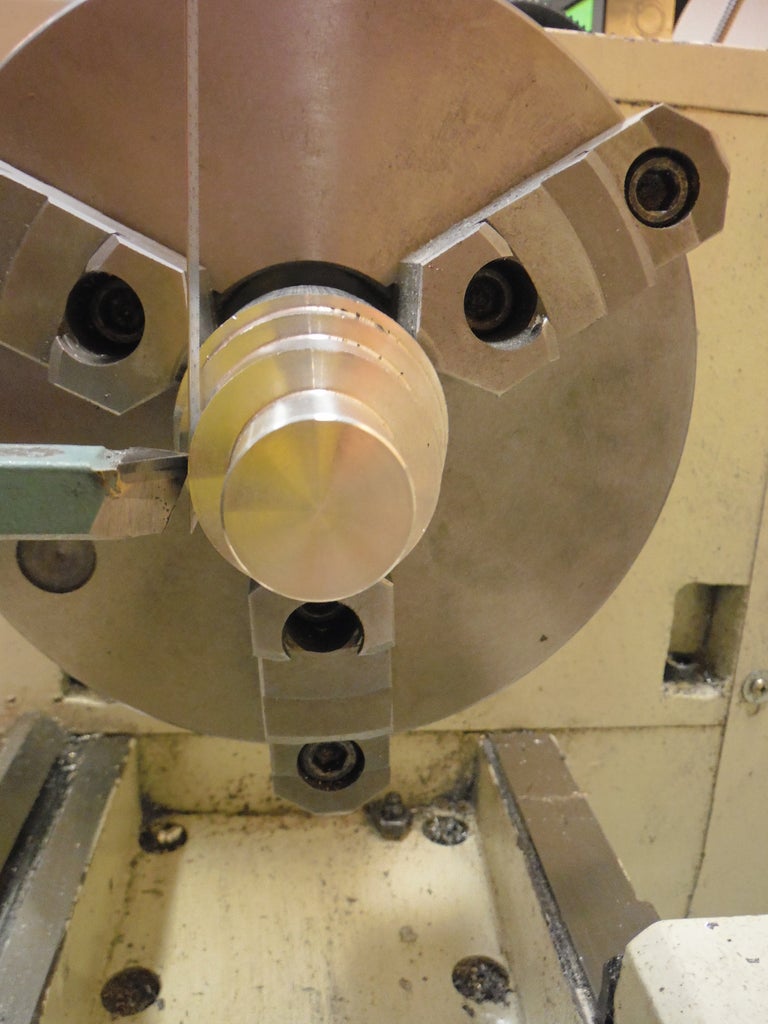

Parting off bowls and lids When turning a bowl on the lathe and holding it by a tenon in a multi-jawed chuck the parting tool can be used to part the bowl from the lathe. 2 x 22mm Parting inserts. 1 x 12mm Parting block suits 26mm blade height.

1 x Key insert remover. When machining with long overhangs it is especially important to mount the bar correctly to ensure enough clamping contact. Turn the outside of the bowl to your desired shape.

Next I took the blade over to the disk sander and ground it down to bare metal. There are several options. Edges faceedge need to be 90 so must be held square to wheel.

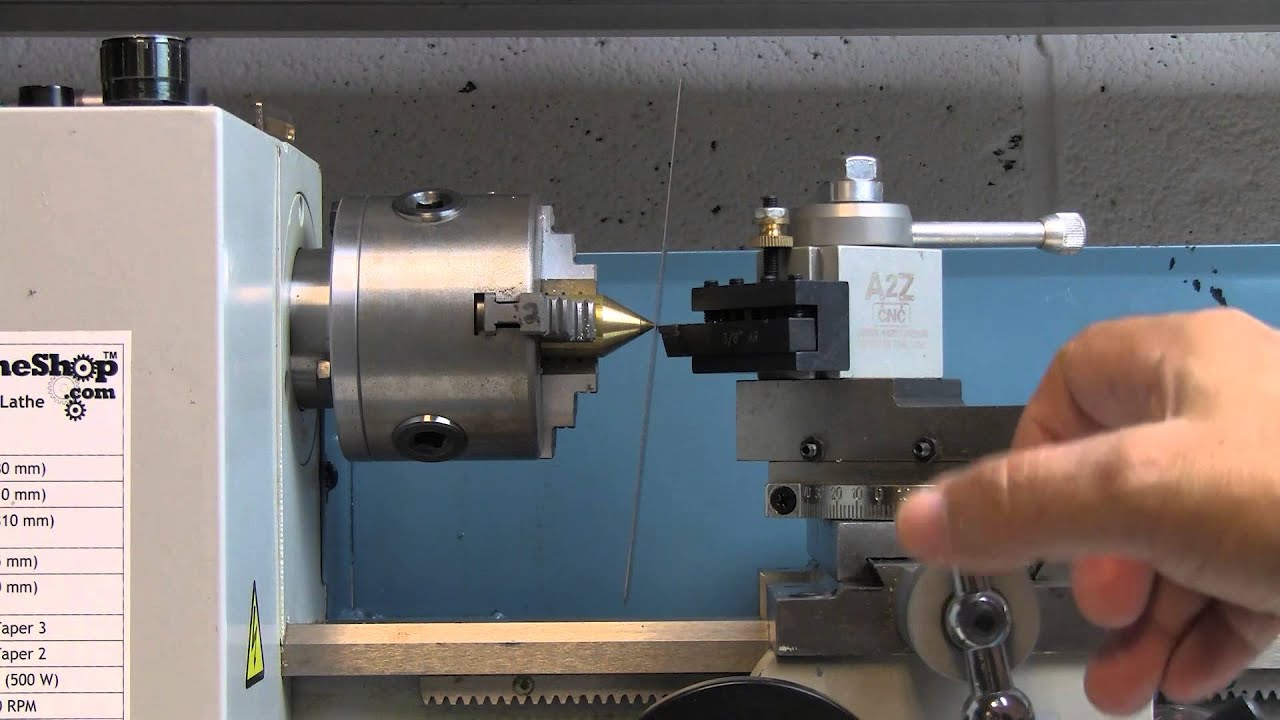

Load your cylindrical part in the chuck of a lathe when you tighten the chuck rotate the part with your hand lightly until it cant move anymore to center the turning part. Parting tools of almost any sort seldom give the best possible finish. Install the tool tight in the holder and set the holder perpendicular to the part.