How To Manage A Cnc Machine Shop

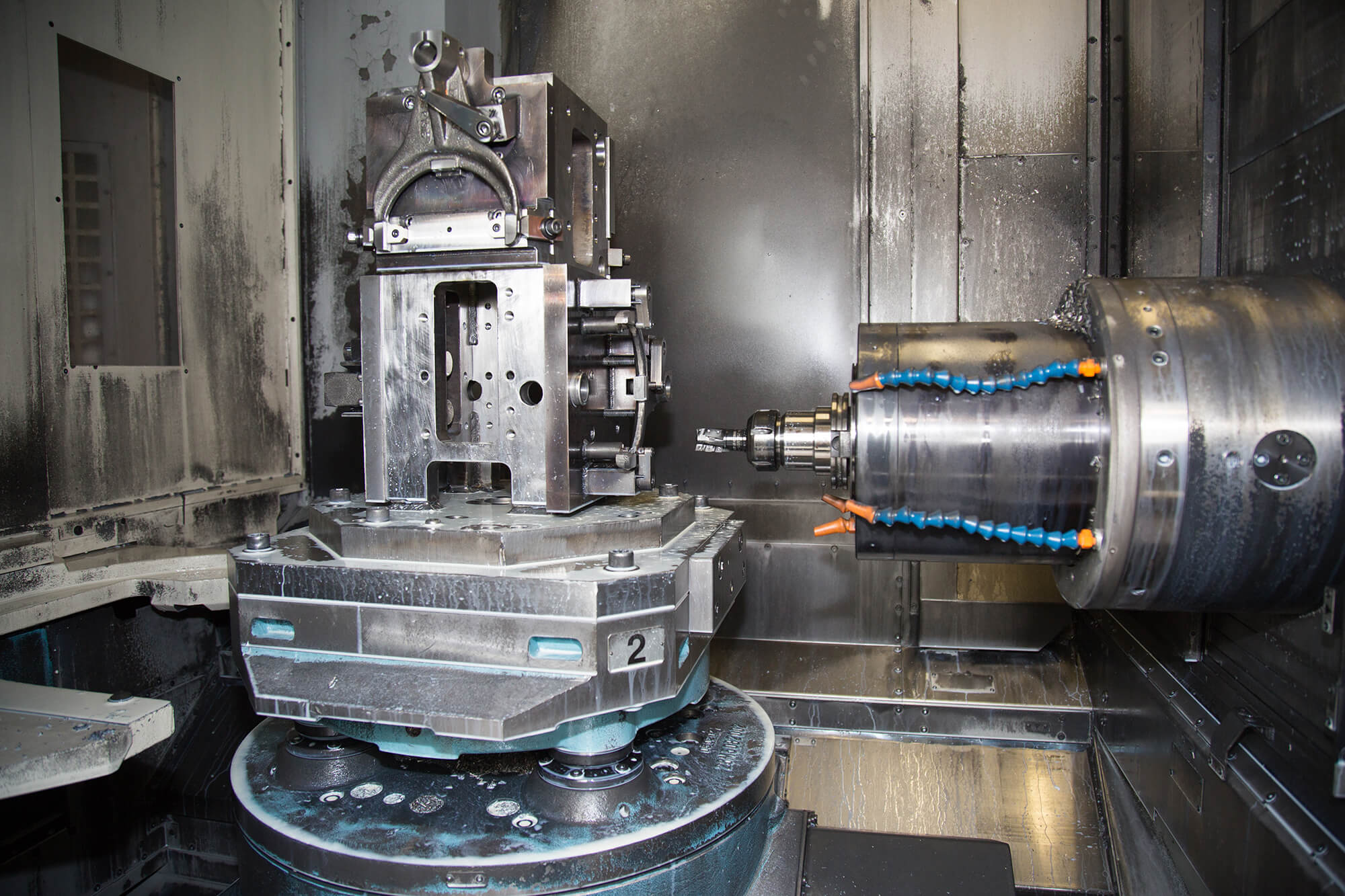

The CNC machine shop is more efficient when all the personnel work together.

How to manage a cnc machine shop. Where and how are our CAM files post-processors and NC programs to be managed. Running a CNC shop is hard. For many start-up machine shop owners the early days can be an uncertain time in which numerous concerns such as volume expectations client lists or even floor plans have yet to be resolved.

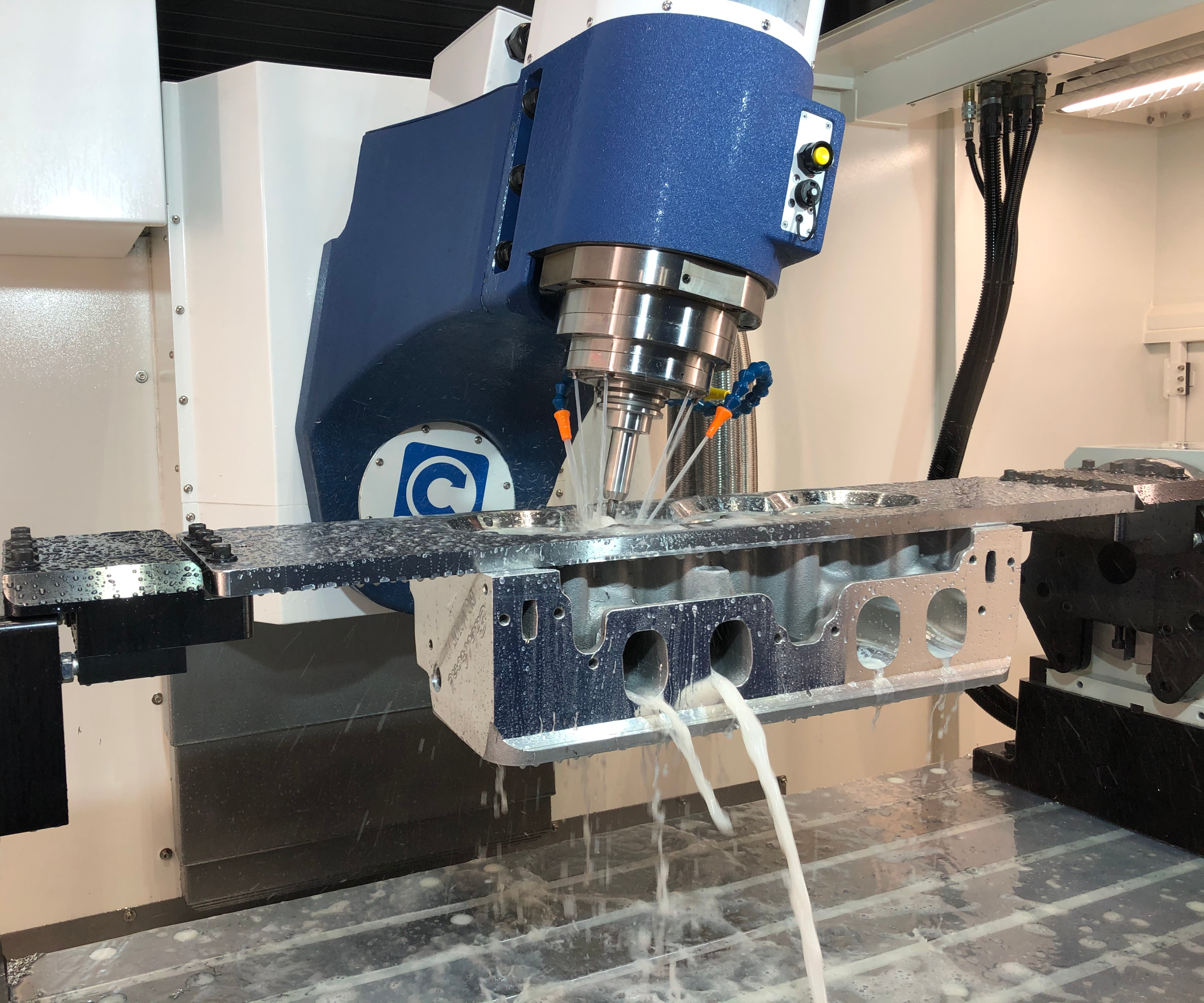

Try doing an inventory of your staff and see whether youve got all the bases covered youd like to have. Executive Editor Modern Machine Shop. CNC Machining Machine Shop Scraps of wood and metal likely cover the surface of your workshop as proof of how hard you work in that space.

It may look like a desk job type book but what it teaches fits very nicely with fabrication machine shop work. How digitalization has changed the machine shop Computer Numerical Control became commonplace in the latter half of the 20th century changing machine shops forever. Ive had numerous folks email asking how I price jobs quote jobs etc.

Here are three main tips for improving your CNC machine shop efficiency and productivity. CNC machine shops. You can also use it to beef up your interview processes to make.

Health and Safety Executive CNC machining Engineering Control Suitable swarf vacuums should be used to remove wet swarfchips from machine surfaces. Because a companys productivity is directly related to the productivity of its CNC machine tools CNC people should be considered among the most important people in a company. Efficiency helps make production run smoothly and eliminates wasted time.

As a machine shop manager there are always many moving parts no pun intended to manage throughout day-to-day operations. However a workshop does not need to be messy and will function much better if it is. 75000 - 85000 a year.