How To Make Your Own Wood Turning Lathe

Usually a piece of 12 steel round or square notched out in the end to accept a small square round or triangular carbide cutter that is screwed onto the steel shaft and the far side of the shaft has a long wood handle.

How to make your own wood turning lathe. Building your own wood lathe is truly a simple matter. Finally you have your tail stock. Nut Type Compression Tube Size 34 In Tube Outside Dia.

There are not a lot of parts needed to make a nice Wood Lathe Tool. To begin with if your were searching for wood turning tools with carbide tips you might have a hard time finding them because these special tools are made with carbide inserts. How to Make Lathe Chuck.

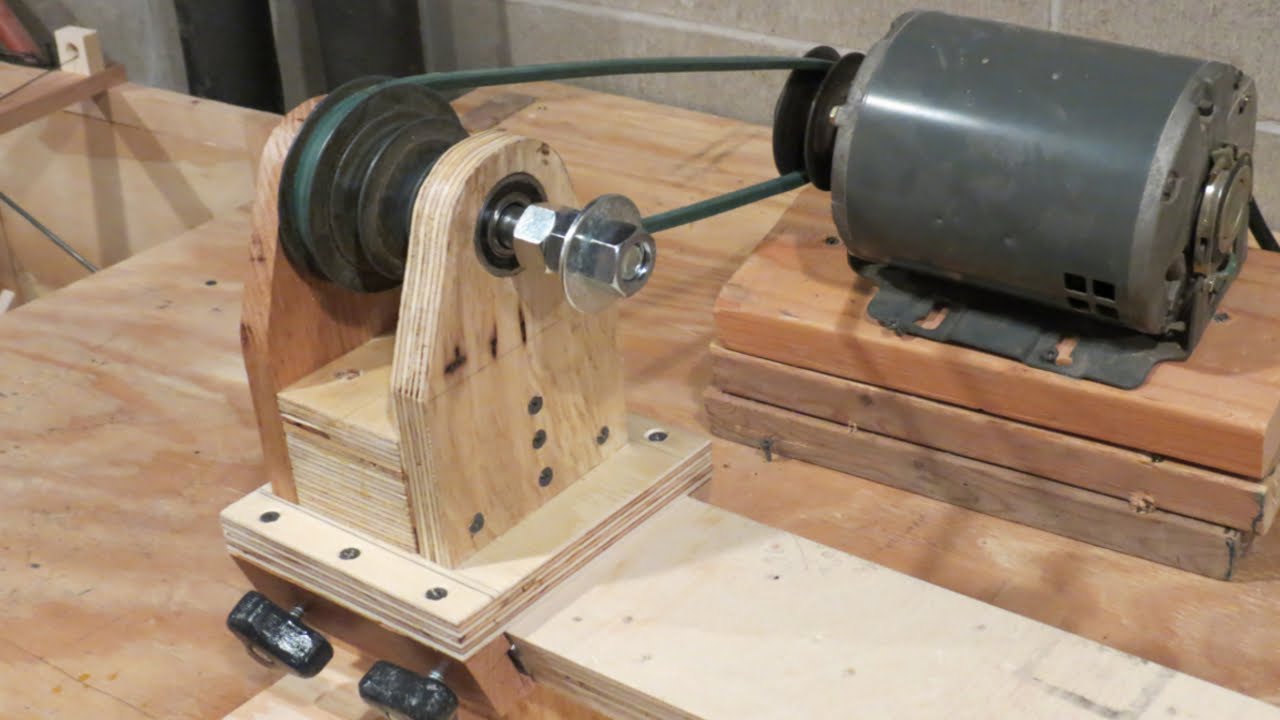

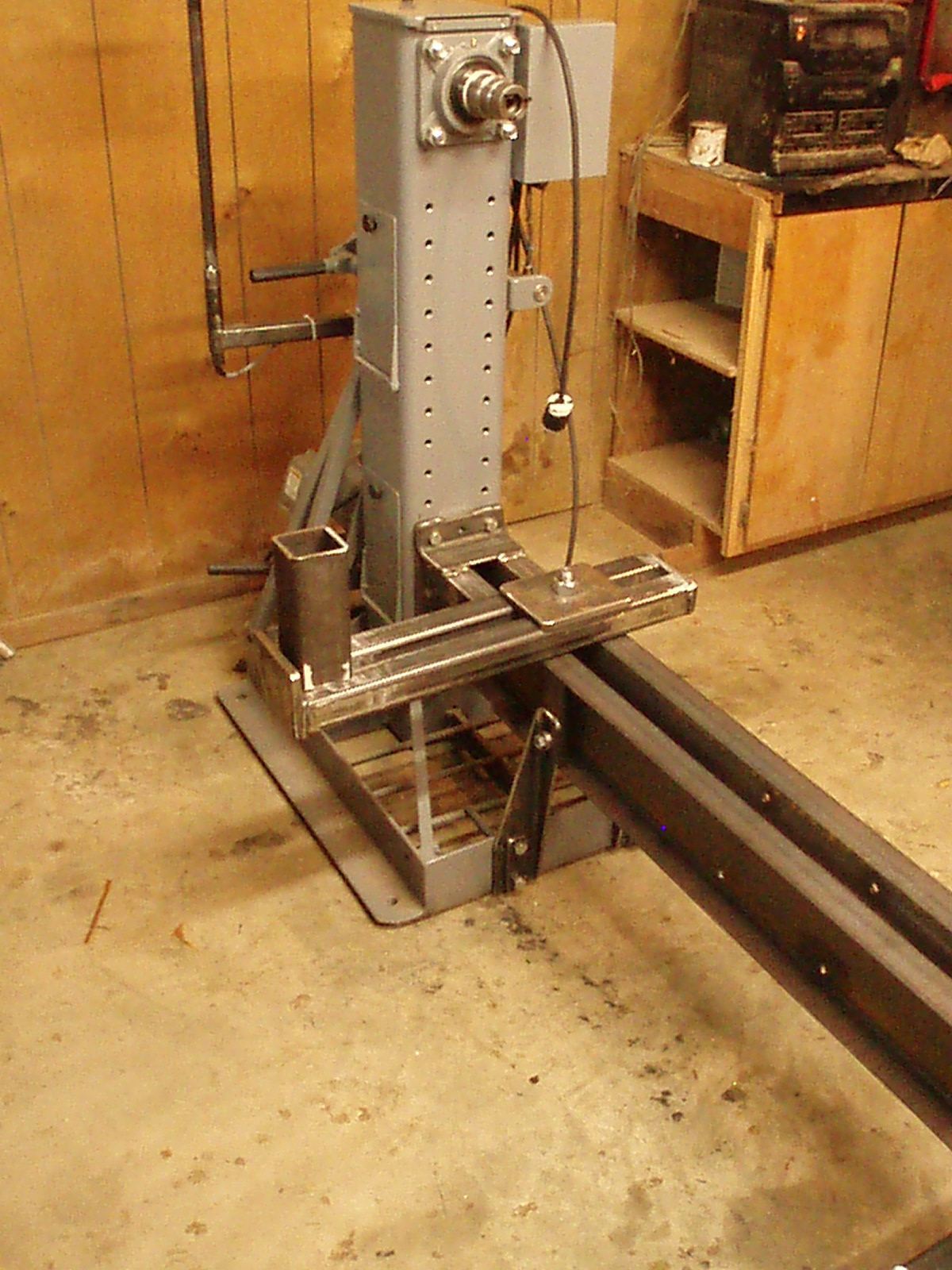

You lathe should look like this. The main thing is to make sure your motor can spin with both a lot of speed and a lot of power. 4-jaw Lathe Chuck for Woodturn.

I think I used a 30 minute epoxy to glue the handles together. But it also shows how you can make your own allowing you to tailor your wood-holders precisely to the work you want to do. Pick up your spindle blank and alight the awl hole with the point on the drive spur.

Make sure you clamp up the handles nice and tight wipe off any excess epoxy that oozes out from the handles being squeezed together. Both my father and I have used vacuum cleaner motors to build both metal and wood turning lathes. Old-school faceplate turning often involves gluing your turning stock here a piece of cherry to a sacrifical piece of wood in the photo a piece of pine that is in turn screwed to the faceplate.

Fixtures and Chucks for Woodturning clearly explains how to get the most from commercial chucks centers and faceplates. Its easier to clean it up now that after it gets hard. In your tail stock put the live center.