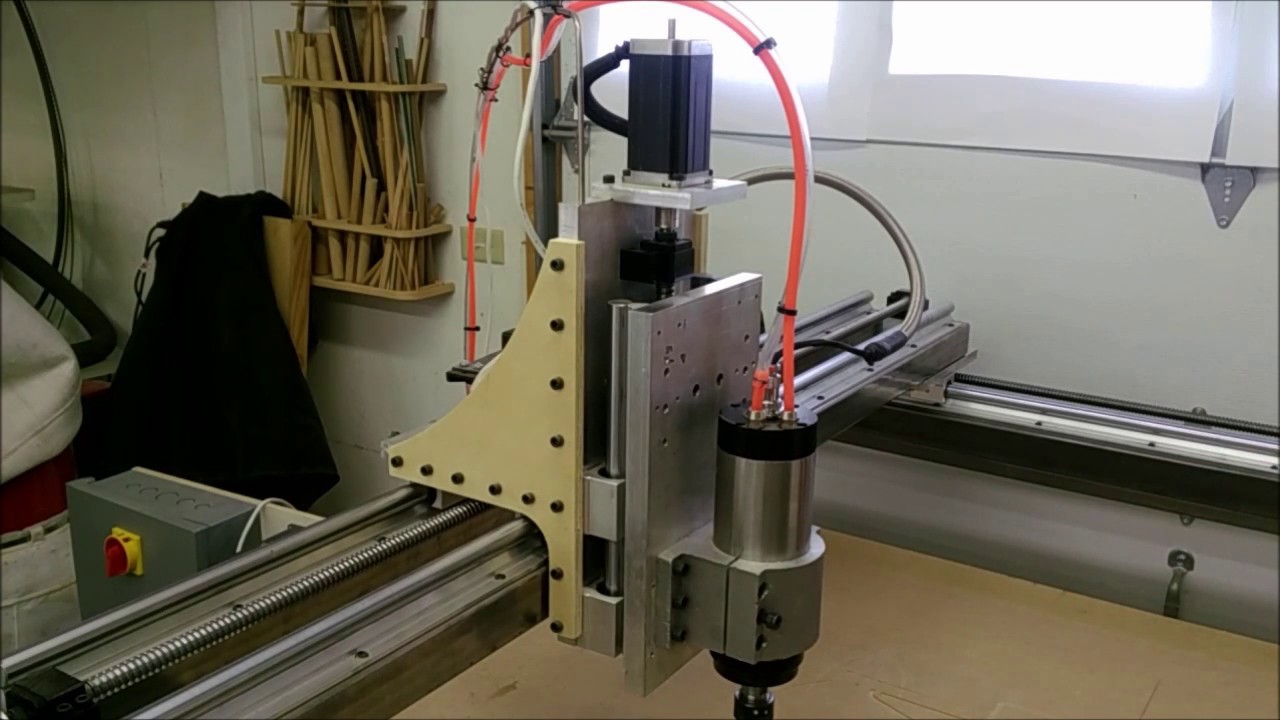

How To Make Your Own Cnc Wood Router

The basic options to drive each axis are.

How to make your own cnc wood router. What kind of linear drive system will you use for each axis. Timing belts rack and pinion and drive screws. Below is a general outline of how a CNC router works and the steps required to create something using one.

With 20 inches wide the kinetic sculpture can run several hours by a single winding. Get the step-by-step plans for this Shop-Built CNC Router here. The main thing to note while preparing the digital image is to remain consistent with any adjustments you make.

CAD Design The first step in the process of cutting something with a CNC is creating a 3-dimensional object of the item you are wanting to cut. Basic digital marketing starting with a social media page is the first step to selling your CNC router business. To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft.

Like many CNC router projects the wood needs to be flat and sanded down with grade 180-240 sandpaper. The next and most expensive step is the electronics. Musical instruments have high requirement on precision and aesthetics.

Before assembling your machine ensure you have these tools. But a few students made some simple modifications and improvements. This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

Build your own CNC explains how to build program and manufacture your own products on your own machine. The quality of your fittings bearings and other motion hardware is important. There are 3 steps to the project Construction Software Manufacture.