How To Make A Parting Tool Holder

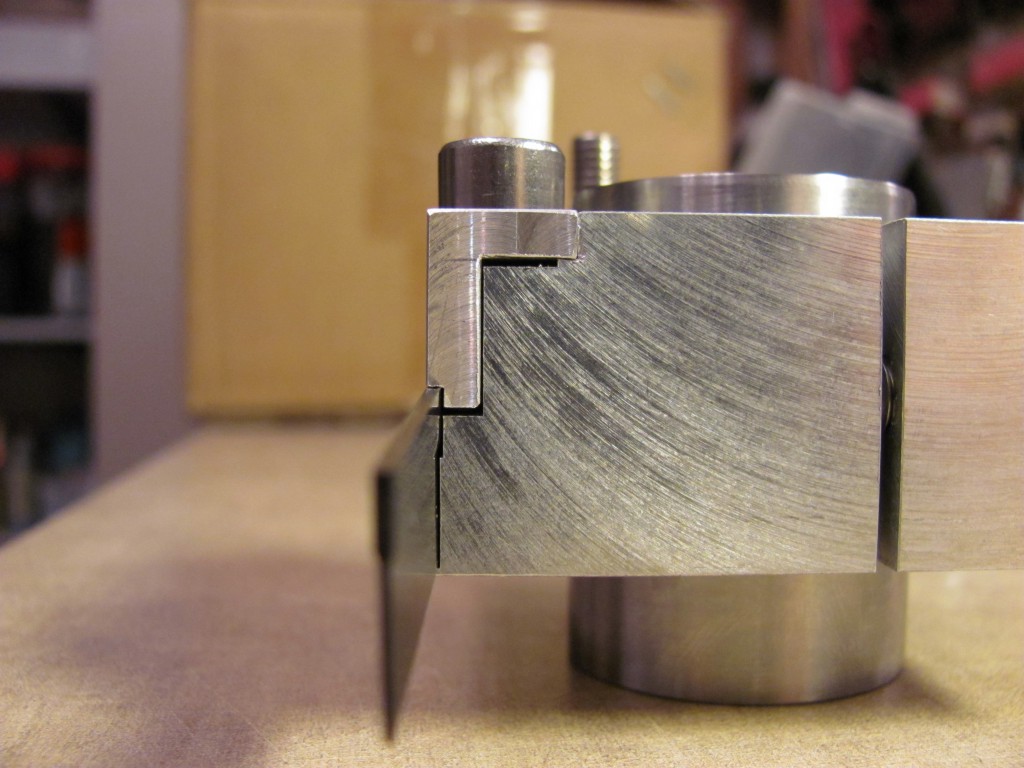

This means that when this tool holder is being used the shank must be at 45 degrees to the left.

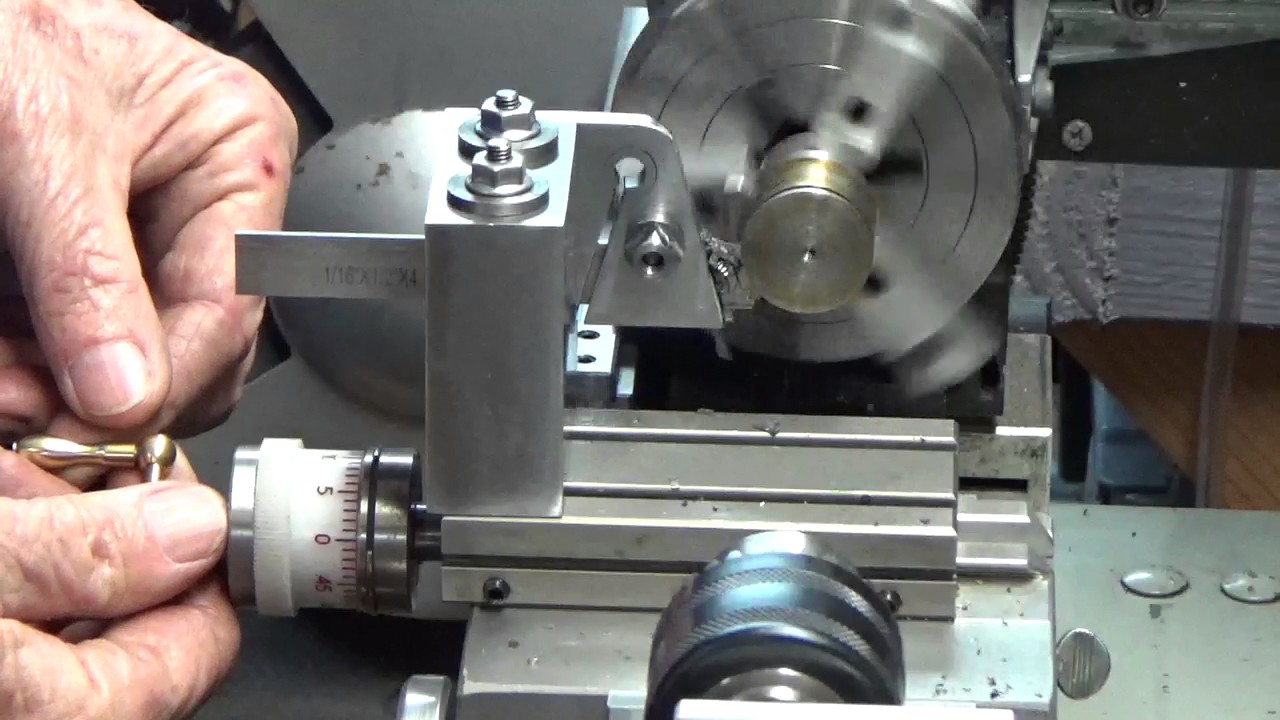

How to make a parting tool holder. Loosen the tool post align the edge of the toolholder flush with the 1-2-3 block and re-tighten the tool post. Now lock the half nut in the engaged position to keep the carriage from moving during the parting cut. The easiest thing to use was a part.

Use a master square to set the tool holder square with the lathe chuck and tighten the nut to lock the tool holder in place. Turn round in chuck and repeat for side wedge hole. For 1 long try the front wedge for a sliding fit.

So I thought I would make my own parting tool for woodturning. I needed a parting tool that would give a little so I based my design on designs I found on the internet. Leave one side with no slot.

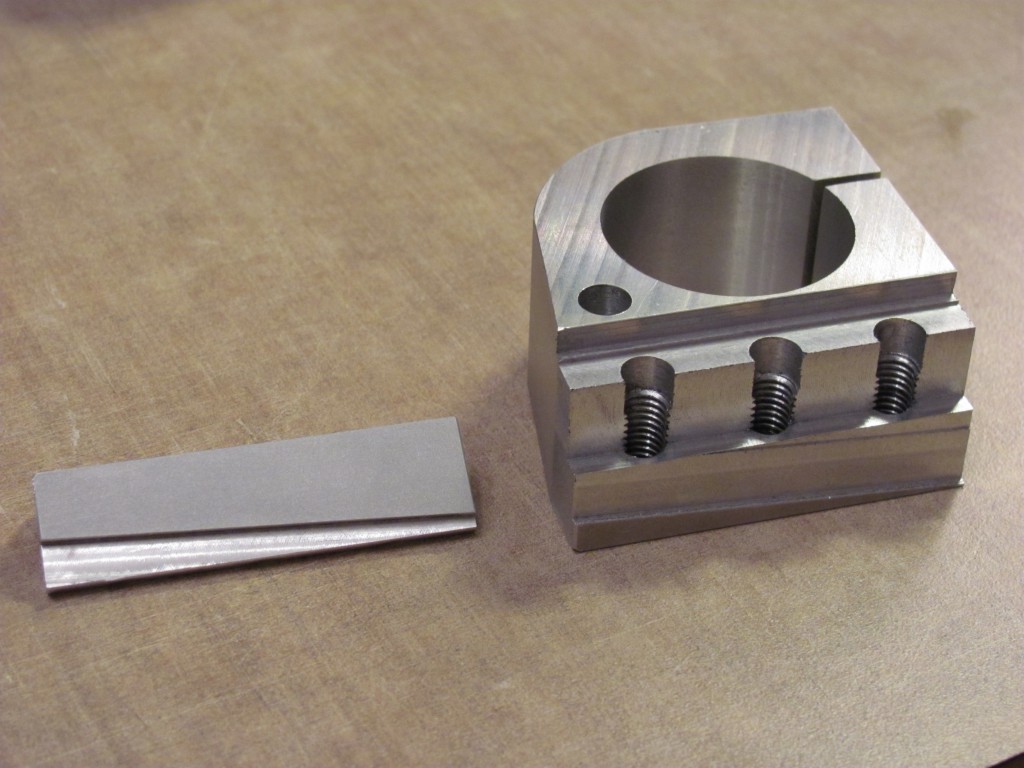

Its made from scrap. Facingturning holder but holds the parting blade inverted. C any other designs that basically does the same thing like parting from the opposite side of the spindleetc.

No matter what holder I make it still has to be adjustable so I could center the blade. I find that locking my carriage is an essential step to take in order to maximize rigidity. If superior tool edge sharpness is not necessary choose a 3-edge or 2-edge insert for a more economical solution or for larger diameters.

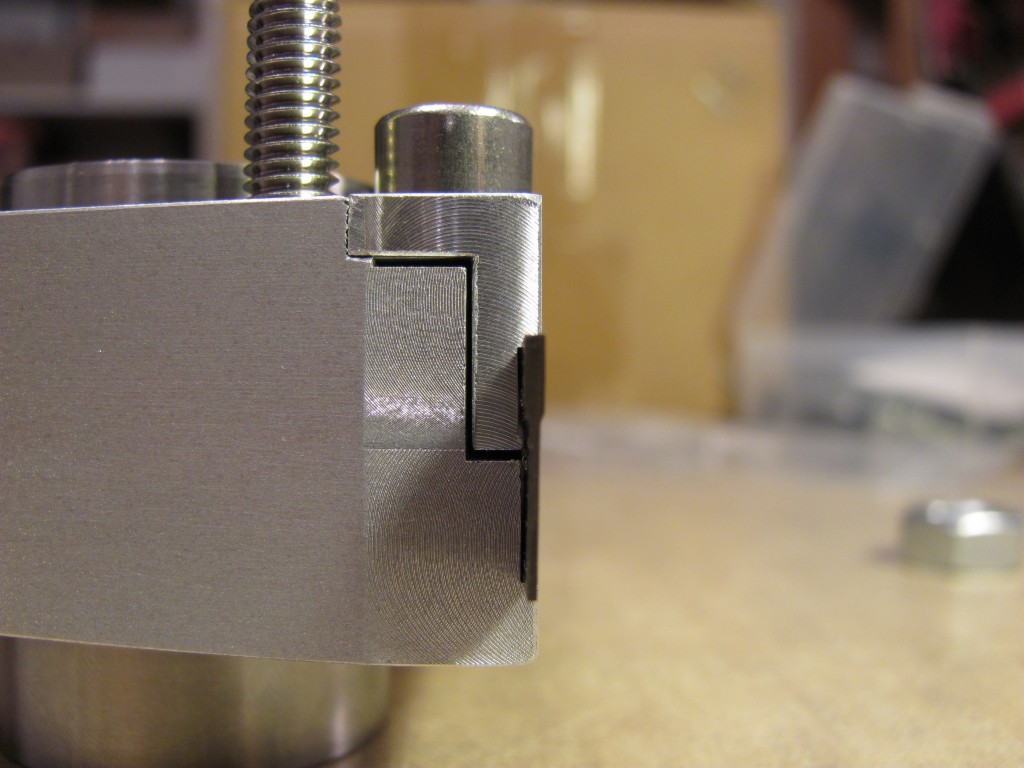

Back view showing how its mounted to the tool holder. Parting cuts should be made at low speed. This is two parts.