How To Make A Homemade Cnc Machine

I created my model in SolidWorks.

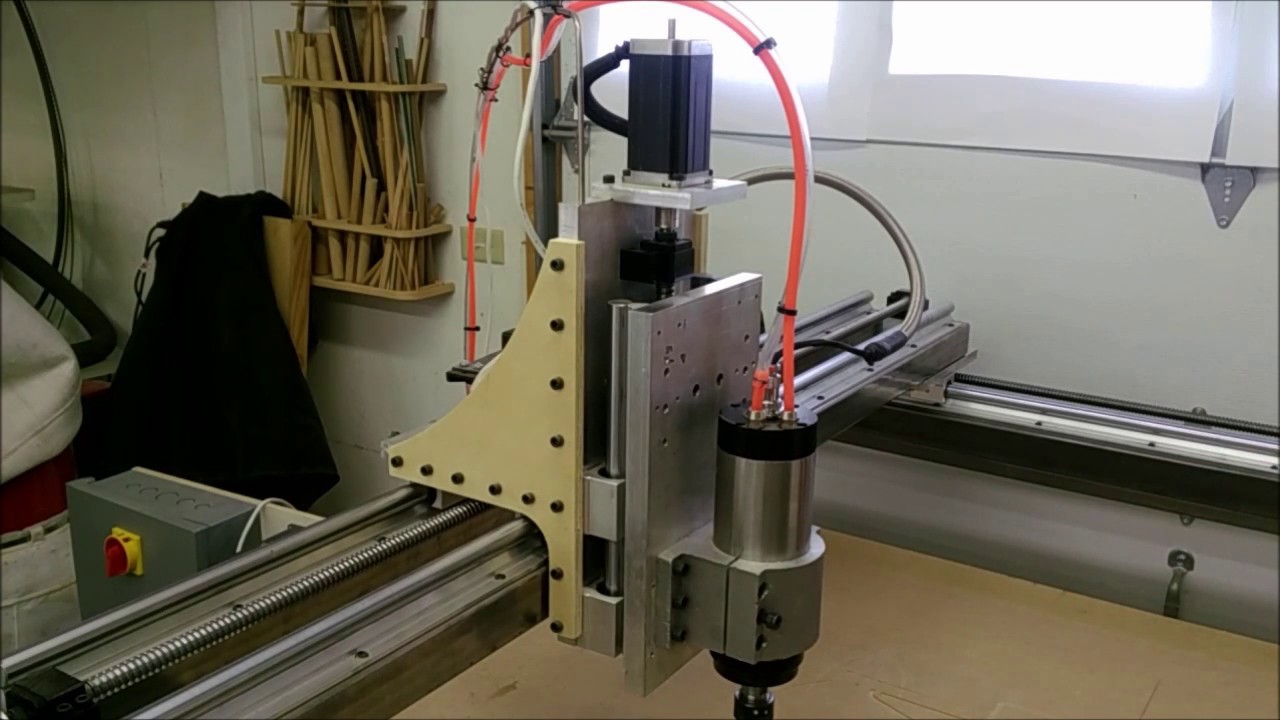

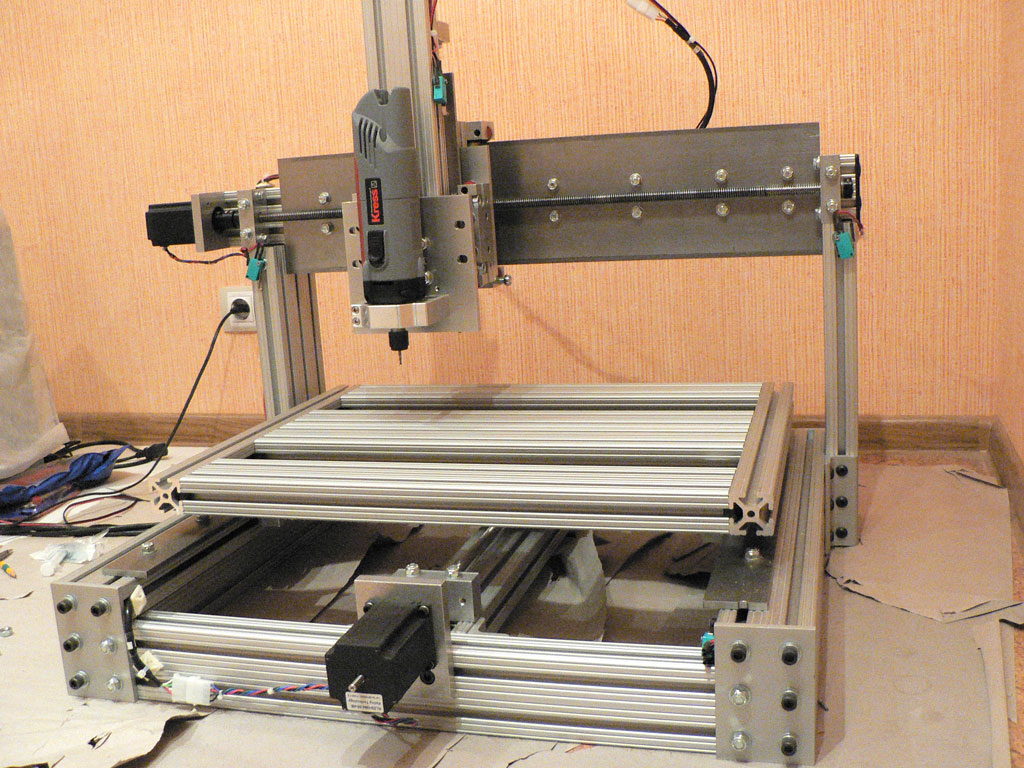

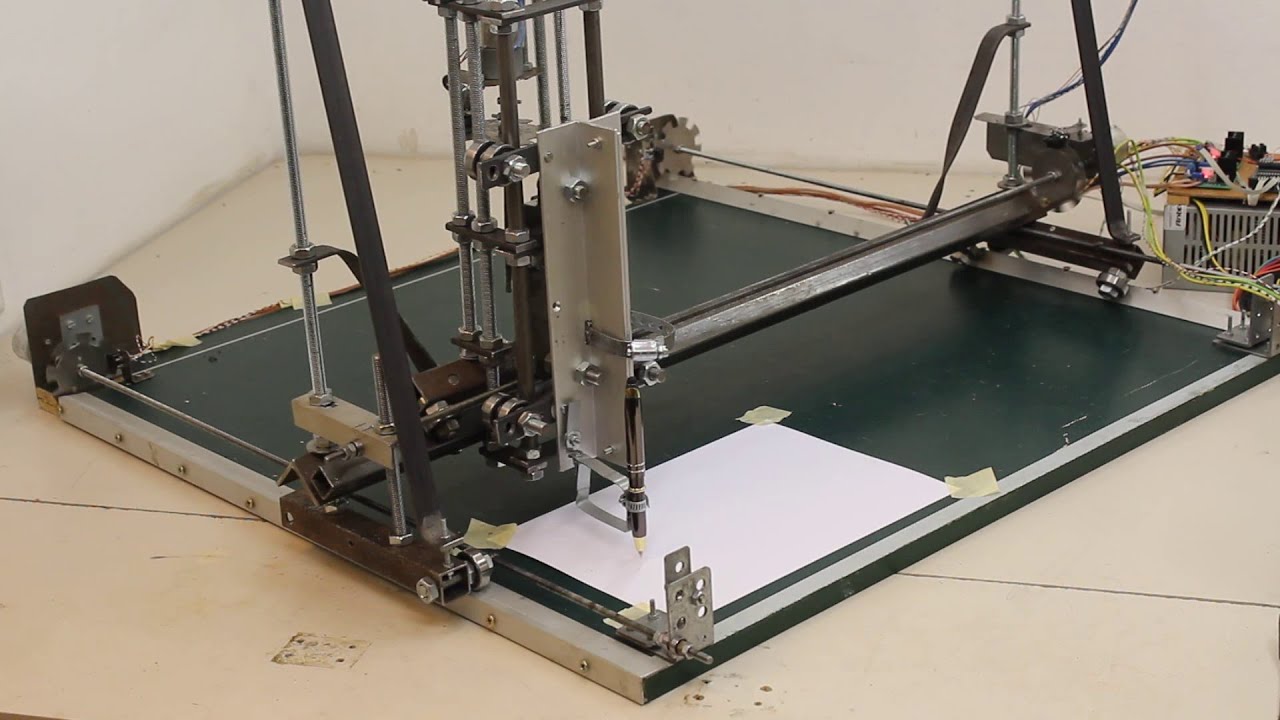

How to make a homemade cnc machine. I recommend taking a look at the following websites. In this video Ill tell you how I made my CNC machine for a 3D treatment and material cutting. This is the second DIY CNC Router I made after learning a lot from building the first version.

Orient with the collar facing the motor and approximately 116 from the face plate. It took me almost 6 months to build and design the machine from start to finish. I needed this milling machine for a new project w.

After doing some research I decided to design and build my own machine. The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors. Here is the condensed version of my 2nd CNC build.

Subscribe to the channel and put your thumbs up. If you want to see more the whole build can be seen in the links below. In this video I show you how I built my DIY CNC machine.

82 Attach four 2 machine screws to the motor mounting holes with washers against the faceplate 83 Thread on a 8 nut and a washer to each machine screw. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are. Enjoy the watching3D mode.

These plans document all the steps I followed to make my DIY CNC Router. These websites will provide you with a ton of information and answer most of your questions on CNC. 84 Feed the machine screws through the mounting holes on the trolley.