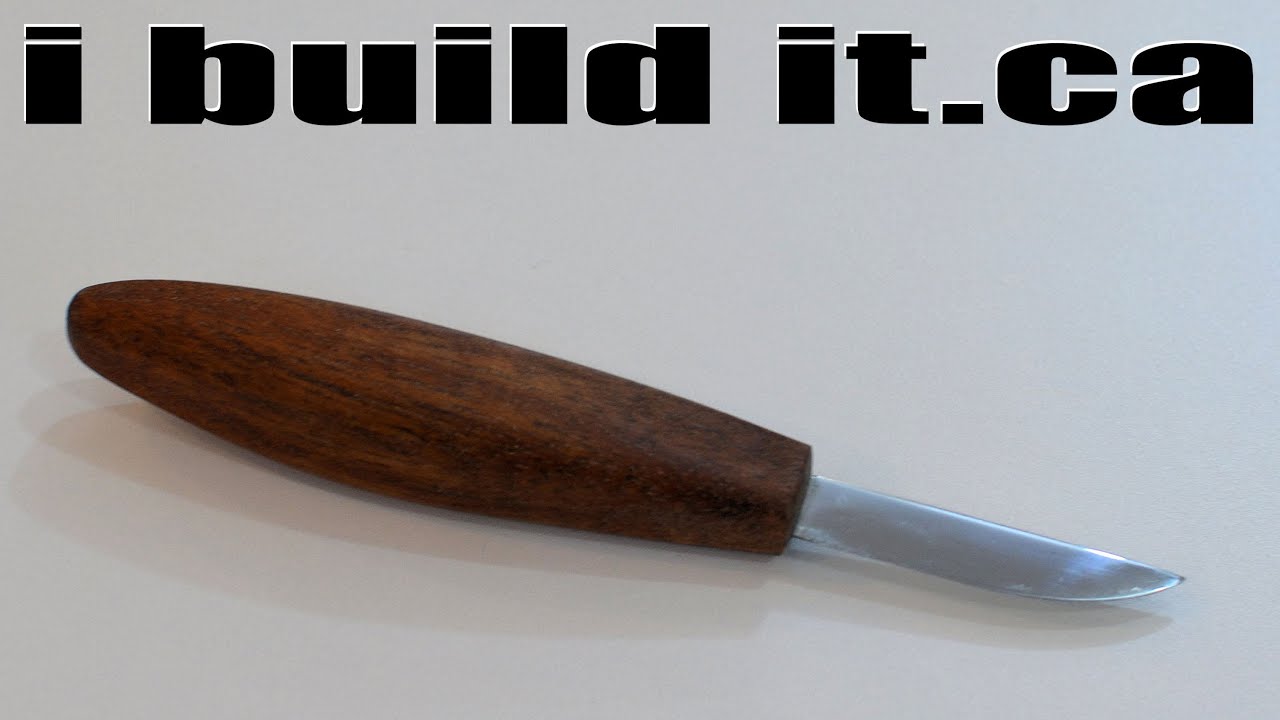

How To Make A Homemade Carving Knife

Kent Andersson Damascus steel.

How to make a homemade carving knife. Use a drill press to make the first hole using the tangs holes as a guide. Handle is sumacHeres how I tempered the blade. When the blade first sits into the wood it is very hard to work that area without damaging the blade and the edge of the carving knife.

A mixture of Boiled linseed oil and bees wax is used to seal and protect the wood. Checking the hardness after I found a file would not cut into the blade so the procedure was successful. This takes time and a small amount of skill to keep the sides of the blade flat and straight.

Start with a 36 to 60 grit sanding belt and finish with 180 or finer. Cover the blade with blue tape while you shape the handle to your liking. Stabilized Buckeye Burl Warthog Tusk Spacer Nickel silver.

450 for 30 minutes let it cool to room temp and do it again. Nordic Verdant Knife Materials. Insert the drill bit into 1 of the holes in the tang.

At this point the knife handle and knife are joined. Use a ruler and a pen to mark a half inch above the tip of the knife and a half inch away from the spine of the knife. Leave the bottom open to slide in your knife.

Split it a few times and with the ax roughly cut the handle into shape. Using these marks cut the folder into a rectangle. This video will show you how to make a wonderful carving knife from repurposed metal and some scrap wood.