Explain The Different Types Of Cutting Tools

Slide and face cutter.

Explain the different types of cutting tools. Iii Cyclic Thermal and Mechanical Load Wear. The cutting edge of the diamond tool is very sharp this is important for cutting chips with very small sections. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter whereas face milling is used for horizontal cutting.

Semi-automatic and automatic improves cutting room productivity and improves cutting accuracy. Fine tooth blades. The wear amount of friction with various metal and non-metal materials is only 150-1800 of cemented carbide which is the most ideal material for cutting tools.

Machining cutting tools range from rough cutting equipment like chop saw or grinder to programmable production oriented machines like the metal mill. These two portions of the cutting tool can be conjoined by following any process including clamping welding and so on. Cutting tools that are frequently used for metalworking include bandsaws broaches and drills.

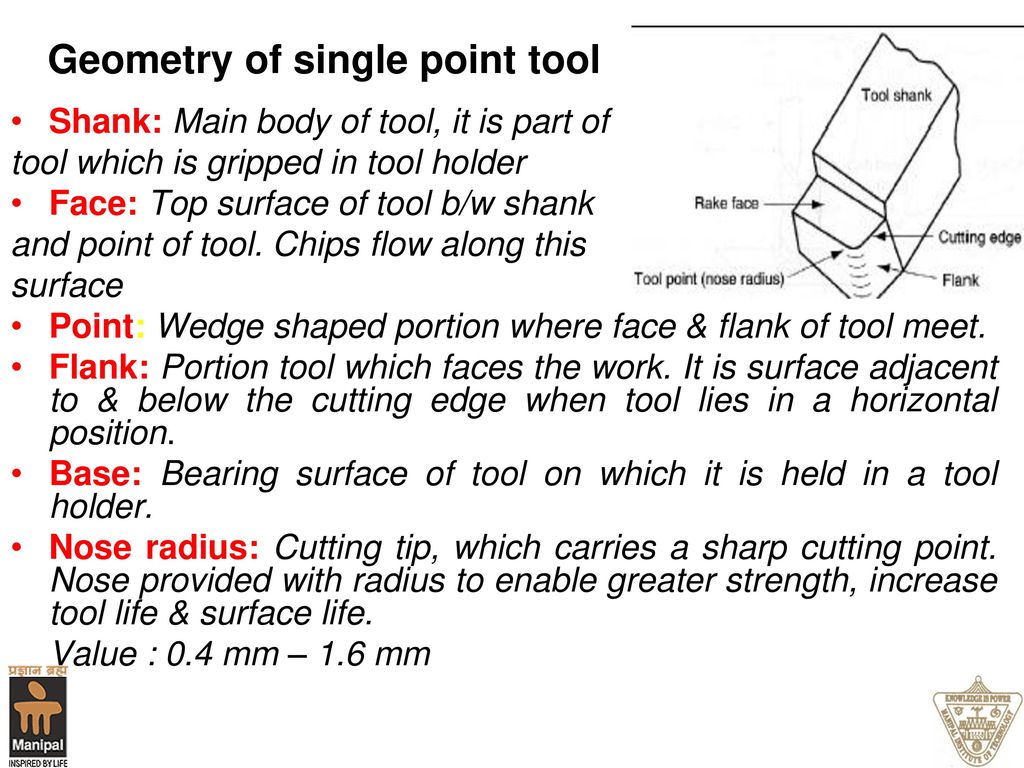

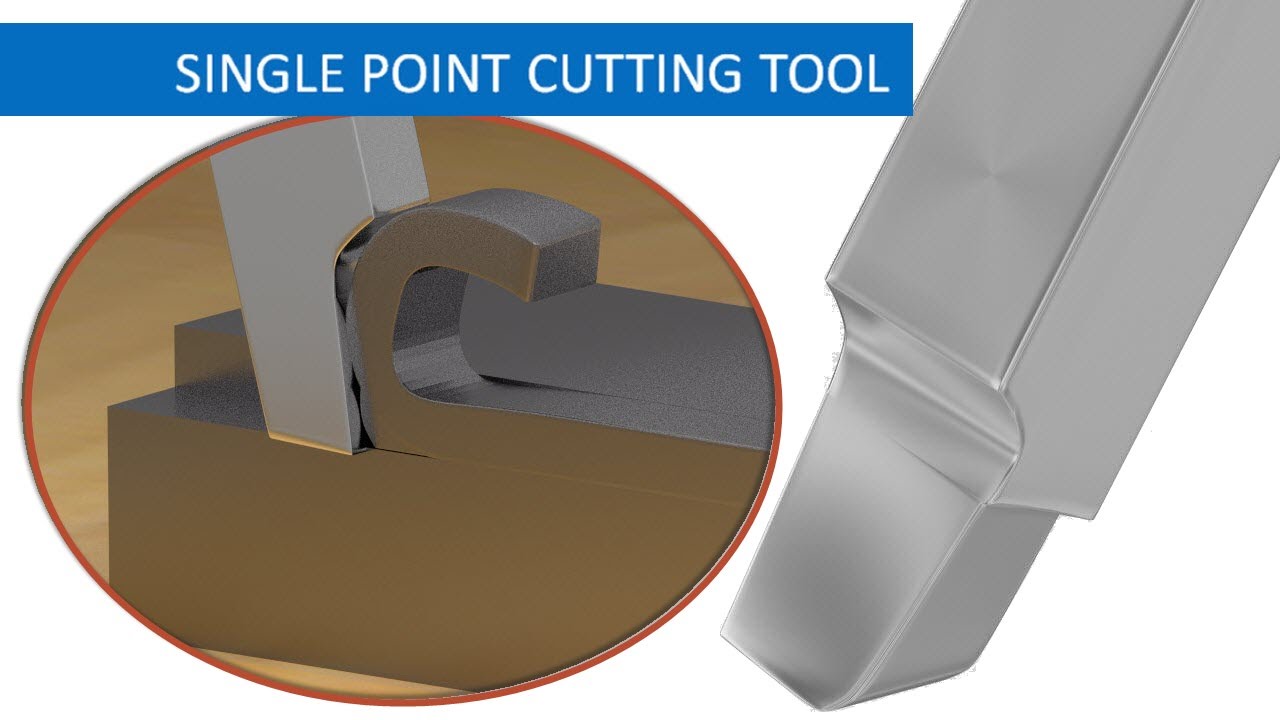

Single -Point Cutting Tool. A few common sizes are 38 34 1 and 1 38. Written by Amrit Kumar in Manufacturing Process Single Point Cutting Tool is a tool that helps to perform several operations like Turning Facing Producing Flat surface on Lathe Shaper Planer Machine.

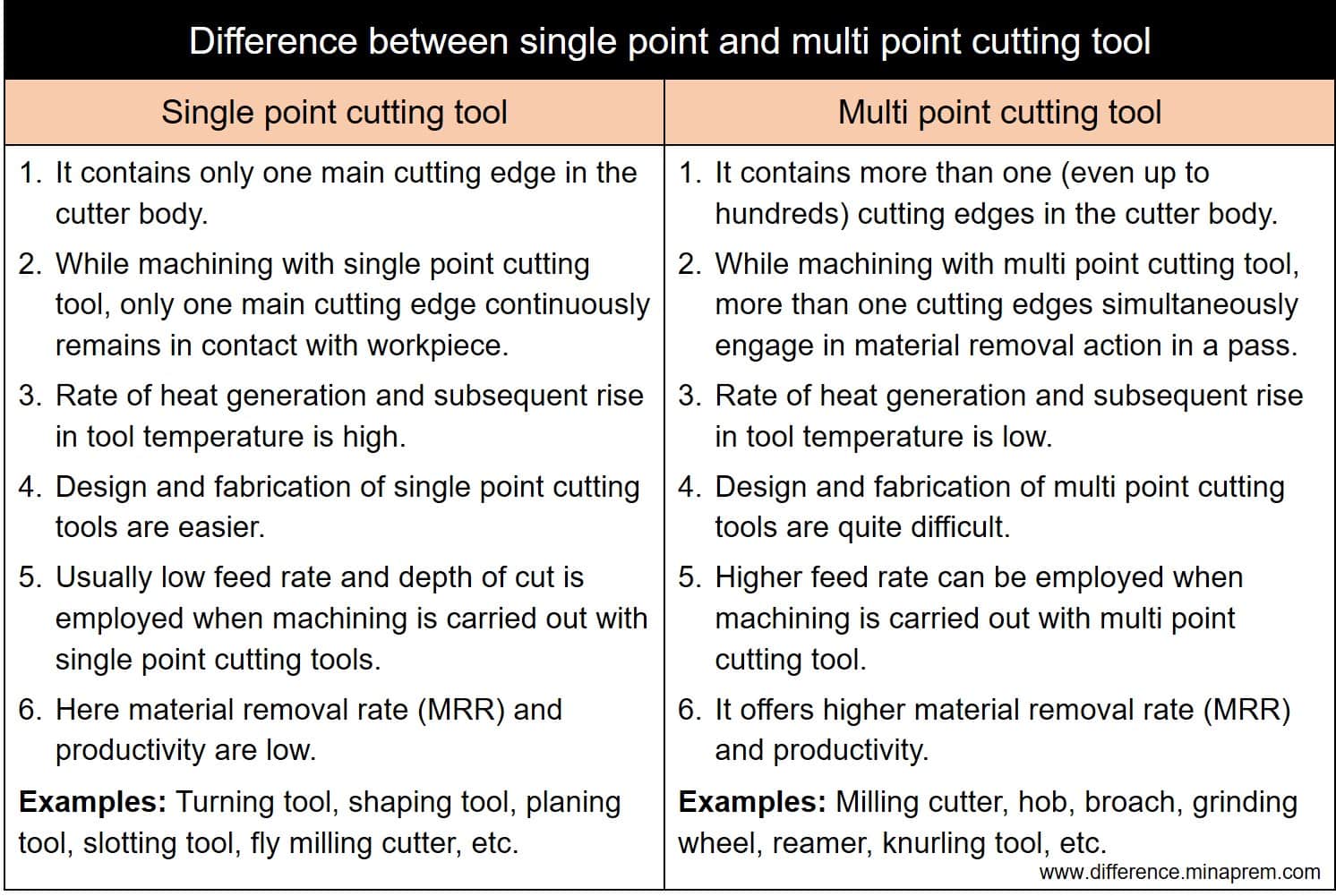

There are two types of cutting tools in this category Single-Point Cutting Tool. Ii Thermal Cracking and Tool Fracture. With respect to the number of the cutting tool used in one tool.

Learn about the different types of cutting tools used by machinists so you can deck out your shop with basic tools for hobby pieces or heavy equipment for industrial-level projects. Built-up edge means the adhesion of work material on the rake face of the cutting tool near the cutting edge. Following are the types of milling cutters that we use in different milling machines.